At present, major lithium battery production enterprises have joined the new track of sodium battery industrialization research and layout. On the one hand, it is in line with the "dual carbon" policy, the inevitable requirement and transformation direction of energy conservation, emission reduction, and the development of clean energy; On the other hand, due to the rapid growth of new energy vehicles, there is a serious mismatch in the supply of lithium resources, and the price of lithium carbonate continues to rise. Upstream costs will sharply rise in the short term, further compressing the profit margins of the middle and downstream.

Wang Fabo, the R&D director of Batwei New Energy, stated that the company had already conducted substantial research and layout in the field of new sodium based secondary batteries a year ago. Due to the basic interoperability between sodium battery production equipment and lithium battery equipment, the working principle is basically similar to that of lithium batteries, both of which involve reversible extraction and insertion of loaded metal ions (Li+/Na+) between electrodes, converting chemical and electrical energy. The R&D team, with profound experience in lithium battery research and mass production, has conducted many experiments, optimizations, and retests on the sodium battery system. They have successfully achieved a breakthrough from zero to one in sodium battery production, and plan to carry out small-scale production by the end of March this year.

At the beginning of the technical route selection, the company comprehensively considered the advantages and disadvantages of three technical routes: layered oxide, Prussian blue (white), and polyanion, and ultimately chose the layered oxide as the positive electrode system technical route. The layered oxide structure is similar to the ternary materials of lithium-ion batteries, with relatively high specific capacity and compaction density. It is easy to synthesize, has a wide range of raw material sources, and is currently the most mature. The industrial transmission path will also be relatively smooth, and it will be the first to have the advantages of industrialization. Therefore, layered oxides are currently one of the most promising positive electrode materials for sodium ion batteries.

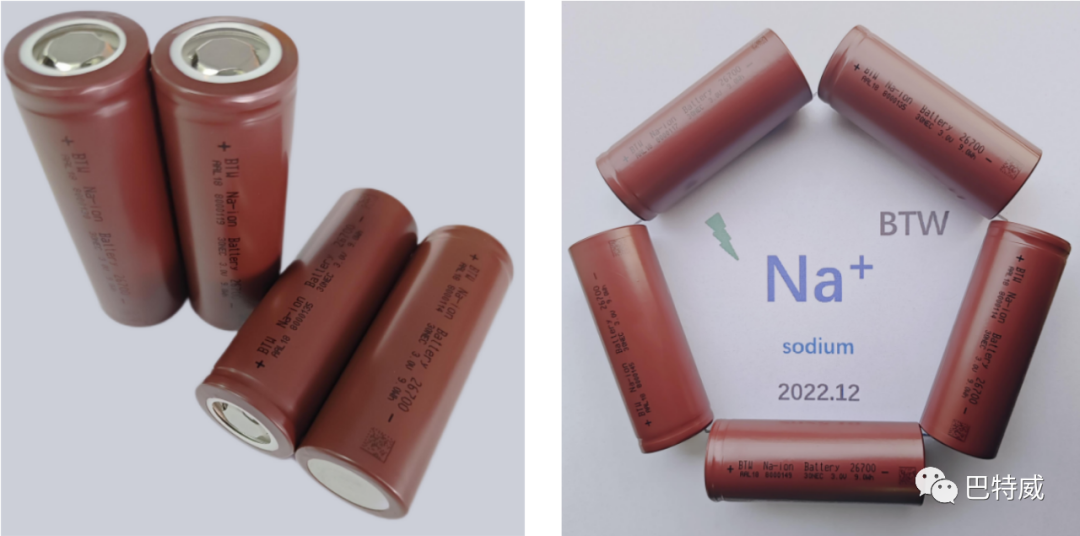

Batway has developed a new generation of cylindrical sodium ion batteries, model BTW 26700-30NEC, by selecting a system with layered oxide as the positive electrode and hard carbon as the negative electrode. This product is positioned in the two wheeled vehicle and energy storage market, with a rated capacity of 3.0Ah, an energy density of 110Wh/kg, a maximum charging rate of 2C, a maximum continuous discharge rate of 5C, an internal resistance of ≤ 20m Ω, a low temperature -20 ℃ discharge capacity retention rate of ≥ 90%, a rate discharge rate of 5C ≥ 96%, and a cycle life of over 2000 times. It can pass safety tests such as short circuits, heavy object impacts, overcharging, compression, and thermal abuse.

In the future, Batway will take three steps in the research and development of sodium batteries. Firstly, it will stabilize the existing 26700-30NEC models in bulk and achieve the ultimate goal; Secondly, we will continue to maintain cooperation with upstream material manufacturers to further optimize and achieve the low-cost advantage of sodium ion batteries. Thirdly, we will continue to develop more new models, relying on their low cost, good rate and low-temperature performance, to form differentiated competitive advantages with lithium batteries in more segmented fields.